1. Mea hoʻopaʻa paʻa

(1) ʻAʻole hiki ke hoʻopaʻa ʻia ka Titanium a me kona mau kumu kumu me ka solder palupalu.ʻO nā metala hoʻopihapiha hoʻopihapiha i hoʻohana ʻia no ka brazing ka nui o ka waihona kālā, kumu alumini, kumu titanium a i ʻole kumu titanium zirconium.

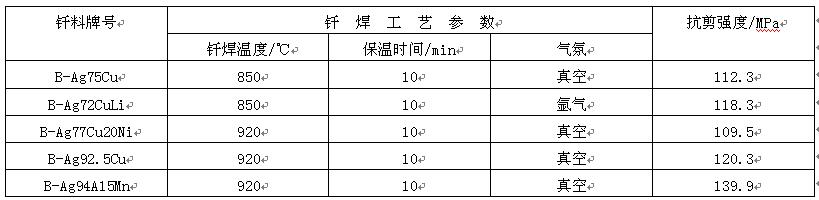

Hoʻohana nui ʻia ka solder e pili ana i ke kālā no nā ʻāpana me ka mahana hana ma lalo o 540 ℃.ʻO nā hui e hoʻohana ana i ka solder kālā maʻemaʻe he haʻahaʻa ka ikaika, maʻalahi e haki, a me ka pale ʻana i ka corrosion a me ka pale oxidation.ʻOi aku ka haʻahaʻa o ka mahana brazing o Ag Cu solder ma mua o ke kālā, akā ke emi nei ka wettability me ka hoʻonui ʻana o Cu maʻiʻo.Hiki i ka Ag Cu solder i loa'a ka li'ili'i li'ili'i o Li ke ho'omaika'i i ka wettability a me ke degere alloying ma waena o ka solder a me ka metala kumu.Loaʻa iā AG Li solder nā hiʻohiʻona o ka helu heheʻe haʻahaʻa a me ka reducibility ikaika.He kūpono ia no ka brazing titanium a me titanium alloys i ka lewa pale.Eia naʻe, e hoʻohaumia ʻia ka umu ahi ma muli o ka hoʻoheheʻe ʻana o Li.ʻO Ag-5al- (0.5 ~ 1.0) ʻO ka metala hoʻopiha Mn ka mea hoʻopiha piha i makemake ʻia no nā ʻāpana titanium alloy ʻoi aku ka paia.ʻO ka hui brazed maikaʻi ka oxidation a me ka pale ʻana i ka corrosion.Hōʻike ʻia ka ikaika ʻoki o ka titanium a me ka titanium alloy i hoʻopaʻa ʻia me ke kumu kālā hoʻopiha metala ma ka Papa 12.

Papa 12 kaʻina hana brazing a me ka ikaika hui o ka titanium a me ka titanium alloys

He haʻahaʻa ka mahana brazing o ka solder e pili ana i ka alumini, ʻaʻole ia e kumu i ka hoʻololi ʻana o ka titanium alloy β Phase e hōʻemi i nā koi no ke koho ʻana i nā mea pono a me nā hale.He haʻahaʻa ka pilina ma waena o ka metala hoʻopiha a me ka metala kumu, a ʻaʻole maopopo ka hoʻoheheʻe ʻana a me ka diffusion, akā maikaʻi ka plasticity o ka metala hoʻopiha, a maʻalahi ke ʻōwili i ka metala hoʻopiha a me ka metala kumu, no laila. kūpono loa no ka brazing titanium alloy radiator, honeycomb structure a me laminate structure.

Loaʻa nā fluxes i hoʻokumu ʻia i ka Titanium a i ʻole titanium zirconium e pili ana i ka Cu, Ni a me nā mea ʻē aʻe, hiki ke hoʻopuehu koke i loko o ka matrix a hana me ka titanium i ka wā brazing, ka hopena i ka matrix corrosion a me ka hoʻokumu ʻana o ka papa brittle.No laila, pono e hoʻopaʻa ʻia ka mahana wela a me ka manawa paʻa i ka wā brazing, a ʻaʻole pono e hoʻohana ʻia no ka hoʻopaʻa ʻana i nā hale paʻa lahilahi i ka hiki.ʻO B-ti48zr48be kahi mea kūʻai maʻamau ʻo Ti Zr.Loaʻa iā ia ka pulu maikaʻi i ka titanium, a ʻaʻohe manaʻo o ka metala kumu i ka ulu ʻana o ka palaoa i ka wā brazing.

(2) ʻO nā metala hoʻopihapiha hoʻopihapiha no ka zirconium a me nā mea hoʻohui kumu e hoʻopaʻa ʻia ana o ka zirconium a me nā alaleʻa kumu e komo pū ana me b-zr50ag50, b-zr76sn24, b-zr95be5, a me nā mea ʻē aʻe, i hoʻohana nui ʻia i ka brazing o nā paipu zirconium alloy o nā mea hoʻolale mana nuklea.

(3) Hiki ke loaʻa nā hopena ʻoluʻolu i ka lewa a me ka lewa inert (helium a me argon) i ka flux brazing a me ka lewa pale.E hoʻohana ʻia ka argon maʻemaʻe kiʻekiʻe no ka pale ʻana i ka argon, a ʻo ka pae hau he -54 ℃ a i ʻole.Pono e hoʻohana ʻia ka fluoride kūikawā me ka chloride o ka metala Na, K a me Li no ka hoʻopaʻa ʻana i ke ahi.

2. ʻenehana brazing

Ma mua o ka brazing, pono e hoʻomaʻemaʻe maikaʻi ʻia ka ʻili, degreased a wehe ʻia ke kiʻi oxide.E hoʻoneʻe ʻia ke kiʻi ʻoniʻoni mānoanoa me ke ʻano mechanical, ke ʻano hoʻoheheʻe one a i ʻole ke ʻano ʻauʻau paʻakai hoʻoheheʻe ʻia.Hiki ke hoʻopau ʻia ke kiʻi ʻoniʻoni lahilahi i loko o ka hopena i loaʻa ka 20% ~ 40% nitric acid a me 2% hydrofluoric acid.

ʻAʻole ʻae ʻia ʻo Ti, Zr a me kā lākou mau ʻāpana e hoʻopili i ka ʻili hui me ka ea i ka wā hoʻomehana brazing.Hiki ke hoʻokō ʻia ka brazing ma lalo o ka pale o ka vacuum a i ʻole inert gas.Hiki ke hoʻohana ʻia ka hoʻomehana induction kiʻekiʻe a i ʻole ka wela i ka pale.ʻO ka hoʻomehana induction ke ala maikaʻi loa no nā ʻāpana symmetrical liʻiliʻi, ʻoiai ʻoi aku ka maikaʻi o ka brazing i ka umu ahi no nā mea nui a paʻakikī.

E koho ʻia ʻo Ni Cr, W, Mo, Ta a me nā mea ʻē aʻe ma ke ʻano he mea hoʻomehana no ka brazing Ti, Zr a me ko lākou mau ala.ʻAʻole e hoʻohana ʻia nā mea hana me ka graphite i hōʻike ʻia ma ke ʻano he mea hoʻomehana e pale aku i ka pollution kalapona.E hana ʻia ka mea hoʻopaʻa paʻa i nā mea me ka ikaika wela kiʻekiʻe, ka helu hoʻonui wela e like me Ti a Zr, a me ka haʻahaʻa haʻahaʻa me ka metala kumu.

Ka manawa hoʻouna: Iune-13-2022