1. Mea hoʻopaʻa paʻa

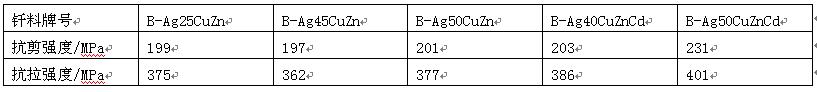

(1)ʻO ka hoʻopaʻa ʻana o ke kila kalapona a me ke kila haʻahaʻa haʻahaʻa e pili ana i ka brazing palupalu a me ka brazing paʻakikī.ʻO ka solder i hoʻohana nui ʻia i ka solder palupalu ʻo ia ka solder lead tin.Hoʻonui ka pulu o kēia mea solder i ke kila me ka piʻi ʻana o ka ʻiʻo tin, no laila pono e hoʻohana ʻia ka mea solder me ka nui o ka tin no ka hoʻopaʻa ʻana i nā hono.Hiki ke hoʻokumu ʻia ka ʻāpana hui intermetallic Fesn2 ma ke kikowaena ma waena o ke kini a me ke kila i loko o ka solder kēpau.I mea e pale aku ai i ka hoʻokumu ʻana o ka pūhui i loko o kēia papa, pono e mālama pono ʻia ka mahana brazing a me ka manawa paʻa.Hōʻike ʻia ka ikaika ʻoki o nā hui kila kalapona i hoʻopaʻa ʻia me nā mea kūʻai alakaʻi tin maʻamau ma ka Papa 1. Ma waena o lākou, ʻo ka ikaika hui pū ʻia me 50% w (SN) ʻoi aku ka kiʻekiʻe, a ʻo ka ikaika hui i welded me ka antimony free solder ʻoi aku ka kiʻekiʻe ma mua o me ka antimony.

Papa 1 ka ikaika ʻohi o nā hui kila kalapona i hoʻopaʻa ʻia me ka solder kēpau

Ke hoʻohana nui ʻia ke keleawe kalapona a me ke kila kila haʻahaʻa, ke keleawe maʻemaʻe, ke keleawe keleawe a me ke keleawe keleawe zinc brazing filler metala.He wahi heheʻe kiʻekiʻe ka keleawe maʻemaʻe a maʻalahi ke hoʻoheheʻe i ka metala kumu i ka wā brazing.Hoʻohana nui ʻia no ka brazing pale kinoea a me ka brazing vacuum.Eia nō naʻe, pono e hoʻomaopopo ʻia ʻo ka ʻokoʻa ma waena o nā hui brazed e emi iho ma mua o 0.05mm e pale aku i ka pilikia ʻaʻole hiki ke hoʻopiha ʻia ka ʻāpana hui ma muli o ka wai maikaʻi o ke keleawe.ʻO ke kila kalapona a me nā hui kila haʻahaʻa i hoʻopaʻa ʻia me ke keleawe maʻemaʻe he ikaika kiʻekiʻe.ʻO ka maʻamau, ʻo ka ikaika shear he 150 ~ 215mpa, aʻo ka ikaika tensile e puʻunaue ʻia ma waena o 170 ~ 340mpa.

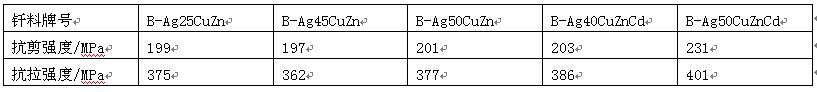

Ke hoʻohālikelike ʻia me ke keleawe maʻemaʻe, ua emi ka helu heheʻe o ke keleawe zinc solder ma muli o ka hoʻohui ʻana o Zn.I mea e pale aku ai i ka hoʻoheheʻe ʻana o Zn i ka wā brazing, ma kekahi ʻaoʻao, hiki ke hoʻohui ʻia kahi mea liʻiliʻi o Si i ka solder zinc copper;Ma ka ʻaoʻao ʻē aʻe, pono e hoʻohana ʻia nā ʻano hoʻomehana wikiwiki, e like me ka lapalapa ahi, induction brazing a me dip brazing.ʻO nā hui o ke kila kalapona a me ke kila kila haʻahaʻa i hoʻopaʻa ʻia me ke keleawe zinc filler metala he ikaika maikaʻi a me ka plasticity.No ka laʻana, ʻo ka ikaika tensile a me ka ikaika shear o nā hui kila carbon brazed me b-cu62zn solder hiki i 420MPa a me 290mpa.ʻOi aku ka haʻahaʻa o ka helu hoʻoheheʻe o ka solder keleawe keleawe ma mua o ke keleawe zinc solder, he mea maʻalahi ia no ka wili kui.He kūpono kēia metala hoʻopiha no ka lapalapa ahi, induction brazing a me ka umu ahi o ke kila kalapona a me ke kila kila haʻahaʻa, akā pono e hoʻemi ʻia ka ʻike o Zn i ka wā hiki i ka wā o ka umu ahi, a pono e hoʻonui ʻia ka helu wela.Hiki ke loaʻa i nā hui me ka ikaika maikaʻi a me ka plasticity ʻo Brazing carbon steel a me ke kila kila haʻahaʻa me ke keleawe keleawe zinc filler metala.Ua helu ʻia nā ʻikepili kikoʻī ma ka Papa 2.

Pākaukau 2 ikaika o nā hui kila kalapona haʻahaʻa i hoʻopaʻa ʻia me ke keleawe keleawe keleawe

(2) Flux: e hoʻohana ʻia ka flux a i ʻole ke kinoea pale no ka hoʻopaʻa ʻana i ke kila kalapona a me ke kila hao haʻahaʻa.Hoʻoholo pinepine ʻia ka flux e ke ʻano metala hoʻopiha i koho ʻia a me ke ʻano brazing.Ke hoʻohana ʻia ka solder lead tin, hiki ke hoʻohana ʻia ka wai hui ʻia o ka zinc chloride a me ka ammonium chloride e like me ka flux a i ʻole nā flux kūikawā ʻē aʻe.ʻO ke koena o kēia flux he mea ʻino loa ia, a pono e hoʻomaʻemaʻe ʻia ka hui ʻana ma hope o ka brazing.

I ka wā e hoʻopaʻa ai me ke keleawe zinc filler metala, e koho ʻia ka fb301 a i ʻole fb302 flux, ʻo ia hoʻi, borax a i ʻole ka hui ʻana o ka borax a me ka waikawa boric;I ka lapalapa ahi, hiki ke hoʻohana ʻia ka hui ʻana o ka methyl borate a me ka formic acid e like me ka brazing flux, kahi e hoʻokani ai ka mahu B2O3 i ke ʻano o ka wehe ʻana i ke kiʻiʻoniʻoni.

Ke hoʻohana ʻia ke keleawe keleawe zinc brazing filler metal, fb102, fb103 a me fb104 brazing fluxes hiki ke koho ʻia, ʻo ia hoʻi, ka hui ʻana o ka borax, boric acid a me kekahi mau fluoride.ʻO ke koena o kēia flux he corrosive i kekahi ʻano a pono e wehe ʻia ma hope o ka brazing.

2. ʻenehana brazing

E hoʻomaʻemaʻe ʻia ka ʻili e hoʻopili ʻia e nā ʻano mechanical a i ʻole kemika e hōʻoia i ka hemo loa ʻana o ke kiʻi oxide a me nā mea organik.ʻAʻole ʻoʻoleʻa loa ka ʻili i hoʻomaʻemaʻe ʻia a ʻaʻole e pili i nā ʻāpana metala a me nā lepo ʻē aʻe.

Hiki ke hoʻopaʻa ʻia ke kila kalapona a me ke kila hao haʻahaʻa e nā ʻano hana brazing maʻamau.I ka wā o ka hoʻopaʻa ʻana o ke ahi, pono e hoʻohana ʻia ke ahi kūʻokoʻa a hoʻemi iki paha.I ka wā o ka hana, pono e pale ʻia ka hoʻomehana ʻana o ka metala hoʻopiha a me ka flux e ka lapalapa e like me ka hiki.ʻO nā ʻano hana hoʻomehana wikiwiki e like me ka induction brazing a me ka dip brazing he kūpono loa ia no ka brazing o ke kila kinai ʻia a me ke kila.I ka manawa like, pono e koho ʻia ke kinai ʻana a i ʻole ka brazing i kahi mahana haʻahaʻa ma mua o ka hoʻoluhi ʻana i mea e pale ai i ka palupalu o ka metala kumu.I ka hoʻopaʻa ʻana i ke kila ikaika kiʻekiʻe haʻahaʻa i ka lewa pale, ʻaʻole wale ka maʻemaʻe kiʻekiʻe o ke kinoea e koi ʻia, akā pono ke hoʻohana ʻia ke kinoea flux e hōʻoia i ka hoʻomaʻemaʻe ʻana a me ka pālahalaha ʻana o ka metala hoʻopiha ma ka ʻili o ka metala kumu.

Hiki ke hoʻoneʻe ʻia ke koena flux e nā ʻano kemika a i ʻole nā hana mechanical.Hiki ke holoi ʻia a hoʻomaʻemaʻe ʻia ke koena o ka flux brazing organik me ka ʻaila, waiʻona, acetone a me nā mea hoʻoheheʻe organik ʻē aʻe;ʻO nā koena o ke kahe ʻino ikaika e like me ka zinc chloride a me ka ammonium chloride e hoʻokaʻawale ʻia i ka wai wai NaOH ma mua, a laila hoʻomaʻemaʻe ʻia me ka wai wela a me ke anuanu;He paʻakikī ka wehe ʻana i nā koena o ka waika boric a me ka boric acid flux, a hiki ke hoʻoholo ʻia e nā ʻano mechanical a i ʻole ka hoʻolulu lōʻihi ʻana i ka wai piʻi.

Ka manawa hoʻouna: Iune-13-2022