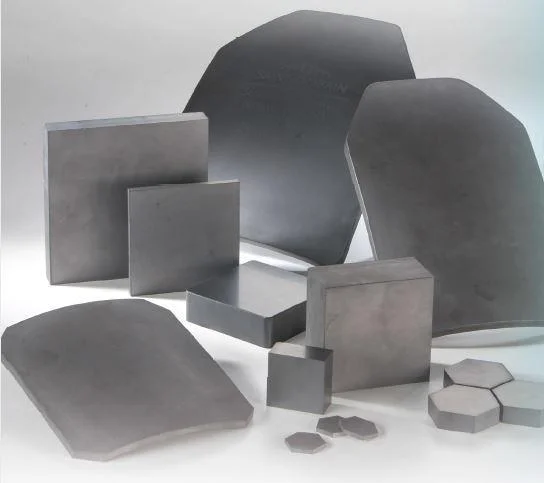

Loaʻa i ka silikon carbide ceramics ka ikaika wela kiʻekiʻe, ke kūpaʻa o ka wela wela, ke kūpaʻa maikaʻi ʻana, ke kūpaʻa wela maikaʻi, ka liʻiliʻi liʻiliʻi o ka hoʻonui ʻana i ka wela, ka conductivity thermal kiʻekiʻe, ka paʻakikī kiʻekiʻe, ke kūʻē ʻana i ka wela, ke kūpaʻa corrosion a me nā waiwai maikaʻi ʻē aʻe. Ua hoʻohana nui ʻia ia i ka kaʻa, ka mīkini, ka mālama ʻana i ke kaiapuni, ka ʻenehana aerospace, ka ʻike uila, ka ikehu a me nā ʻano ʻē aʻe, a ua lilo i mea hoʻololi ʻole ʻia me ka hana maikaʻi loa i nā ʻoihana ʻoihana. ʻĀnō e hōʻike wau iā ʻoe!

ʻO ka hoʻopaʻa paʻa ʻole

Manaʻo ʻia ʻo Pressureless sintering ʻo ke ʻano hoʻohiki maikaʻi loa no ka sintering SiC. E like me nā ʻano hana sintering ʻokoʻa, hiki ke hoʻokaʻawale ʻia ka sintering pressureless i ka sintering solid-phase a me ka wai-phase sintering. Ma o ka ultra-fine β- Ua hoʻohui ʻia ka nui kūpono o B a me C (maʻiʻo oxygen ma lalo o 2%) i ka pauka SiC i ka manawa like, a me s. Ua hoʻopaʻa ʻia ʻo proehazka i ke kino sintered SiC me ka haʻahaʻa kiʻekiʻe ma mua o 98% ma 2020 ℃. A. Mulla et al. Ua hoʻohana ʻia ʻo Al2O3 a me Y2O3 e like me nā mea hoʻohui a hoʻopaʻa ʻia ma 1850-1950 ℃ no 0.5 μm β- SiC (ʻo ka ʻili o ka ʻāpana he wahi liʻiliʻi o SiO2). ʻOi aku ka nui o ka nui o nā seramika SiC ma mua o 95% o ka nui o ka manaʻo, a he liʻiliʻi ka nui o ka palaoa a me ka nui awelika. ʻO 1.5 microns.

Paʻi paʻi wela

Hiki ke hoʻopaʻa paʻa wale ʻia ʻo SiC maʻemaʻe i ka wela kiʻekiʻe loa me ka ʻole o nā mea hoʻohui sintering, no laila nui ka poʻe e hoʻokō nei i ke kaʻina hana sintering wela no SiC. Ua nui nā hōʻike e pili ana i ka sintering wela o SiC ma o ka hoʻohui ʻana i nā mea kōkua sintering. ʻO Alliegro et al. Ua aʻo ʻia i ka hopena o ka boron, aluminika, nickel, hao, chromium a me nā mea hoʻohui metala ʻē aʻe ma ka densification SiC. Hōʻike nā hopena i ka alumini a me ka hao ka mea hoʻohui maikaʻi loa e hoʻolaha i ka sintering wela wela SiC. Ua aʻo ʻo FFlange i ka hopena o ka hoʻohui ʻana i ka nui like ʻole o Al2O3 ma nā waiwai o ka SiC i kaomi wela. Manaʻo ʻia ʻo ka densification o ka SiC paʻa wela e pili ana i ke ʻano o ka hemo a me ka ua. Eia naʻe, hiki i ke kaʻina hana sintering wela ke hana i nā ʻāpana SiC me ke ʻano maʻalahi. ʻO ka nui o nā huahana i hana ʻia e ke kaʻina hana sintering wela hoʻokahi manawa he liʻiliʻi loa, ʻaʻole kūpono i ka hana ʻoihana.

ʻO ka hoʻopaʻa ʻana i ka sintering isostatic wela

I mea e lanakila ai i nā hemahema o ke kaʻina hana sintering maʻamau, ua hoʻohana ʻia ke ʻano B-type a me C-type ma ke ʻano he mea hoʻohui a ua hoʻohana ʻia ka ʻenehana hoʻoheheʻe isostatic wela. Ma 1900 ° C, loaʻa nā seramika crystalline maikaʻi me ka nui o ka nui ma mua o 98, a ʻo ka ikaika kulou i ka lumi wela hiki ke hiki i 600 MPa. ʻOiai ʻo ka isostatic pressing sintering hiki ke hoʻopuka i nā huahana paʻakikī me nā ʻano paʻakikī a me nā waiwai mechanical maikaʻi, pono e hoʻopaʻa ʻia ka sintering, he paʻakikī ke hoʻokō i ka hana ʻoihana.

Ka hoʻopaʻa ʻana

ʻO Reaction sintered silicon carbide, i ʻike ʻia ʻo ka silicon carbide paʻa ponoʻī, pili i ke kaʻina hana i hana ai ka porous billet me ke kinoea a i ʻole ka wai wai e hoʻomaikaʻi ai i ka maikaʻi o ka billet, hoʻemi i ka porosity, a me nā huahana i hoʻopau ʻia me ka ikaika a me ka pololei. e lawe i ka α- SiC pauda a me ka graphite i hui pū ʻia i kekahi ʻāpana a hoʻomehana ʻia i kahi 1650 ℃ e hana i kahi billet square. I ka manawa like, komo a komo i loko o ka billet ma o ke kinoea Si a hana me ka graphite e hana i ka β-SiC, i hui pū ʻia me nā ʻāpana α-SiC. Ke hoʻokomo piha ʻia ʻo Si, hiki ke loaʻa ke kino sintered hopena me ka nui piha a me ka nui ʻole shrinkage. Ke hoʻohālikelike ʻia me nā kaʻina hana sintering ʻē aʻe, he liʻiliʻi ka hoʻololi ʻana o ka hoʻololi ʻana o ka sintering i ke kaʻina densification, a hiki ke hoʻomākaukau ʻia nā huahana me ka nui kūpono. Eia nō naʻe, ʻo ka loaʻa ʻana o ka nui o SiC i loko o ke kino sintered e ʻoi aku ka maikaʻi o nā waiwai wela o ka hopena sintered SiC ceramics.

Ka manawa hoʻouna: Jun-08-2022