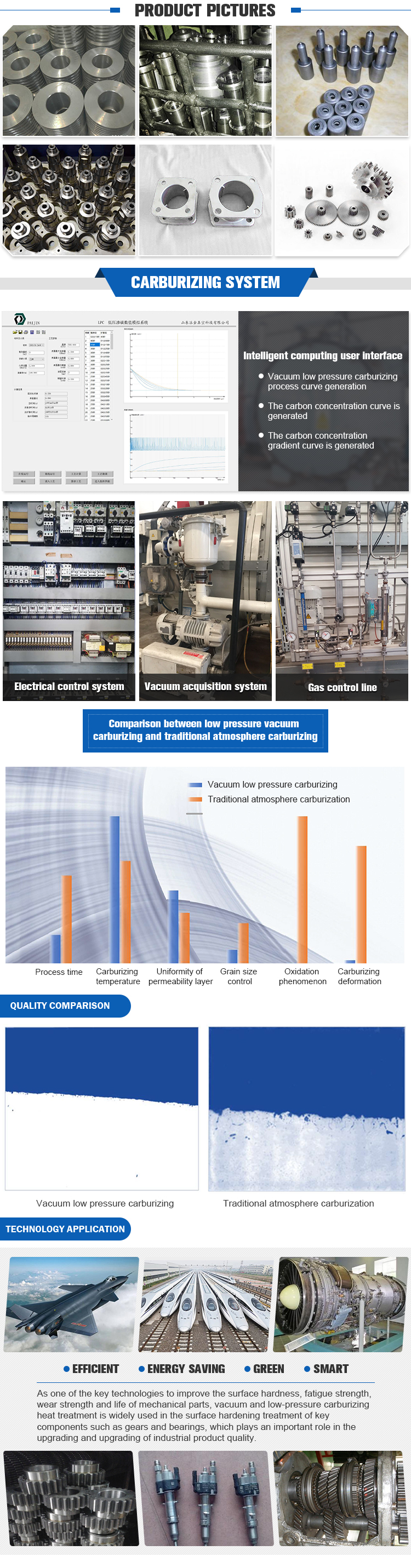

ʻO ka umu carburizing haʻahaʻa haʻahaʻa me ka simulate a me ka ʻōnaehana hoʻomalu a me ka ʻōnaehana hoʻopau kinoea

Palapala noi

Hoʻokahi keʻena hoʻokaʻawale haʻahaʻa haʻahaʻa ʻo Carburizing gas kinai ʻana i ka umu (e hoʻoluʻu ʻia eʻano holo kinoea kūʻokoʻa) he nui nā hana e like me ka carburizing, hoʻopau kinoea a me ke kaomihoʻoluʻu ea. Hoʻohana nui ʻia no ka quenching, annealing, tempering of the die steel, theke kila kila, ke kila kiʻekiʻe kiʻekiʻe, nā hana higent e like me hoʻokahi manawa kiʻekiʻe-carburizing, pulse carburizing a pēlā aku.

Pūnaehana LPC

Ma ke ʻano he ʻenehana nui e hoʻomaikaʻi ai i ka paʻakikī o ka ʻili, ka ikaika luhi, ka ikaika a me ke ola lawelawe o nā ʻāpana mechanical, hoʻohana nui ʻia ka vacuum low-pressure carburizing heat treatment i ka mālama paʻakikī o ka ʻili o nā mea nui e like me nā gears a me nā bearings. Vacuum haʻahaʻa-puʻi carburizing i nā hiʻohiʻona o kiʻekiʻe ka pono, ikehu hoola, omaomao a me ka naʻauao, a ua lilo i ka nui carburizing hana popularized ma Kina ka wela lapaʻau 'oihana.

Ua hoʻohana maikaʻi ʻia ka polokalamu simulation carburizing haʻahaʻa haʻahaʻa i hoʻomohala ʻia e Shandong paijin Vacuum Technology Co., Ltd., a ua hoʻomaka ʻia nā mea hana a me nā kaʻina hana o ka umu haʻahaʻa haʻahaʻa carburizing quenching umu no ka ʻoihana. Hoʻopiha kēia papahana i ke āpau i hilinaʻi mau ai ke kaʻina hana hoʻopiʻi carburizing haʻahaʻa haʻahaʻa home a me nā lako i ka lawe ʻana mai, a ua kau i kahi kumu paʻa no ka hoʻomohala ʻana i ka ʻoihana mālama wela o ka ʻāina e hoʻomaikaʻi i ka maikaʻi a me ka wikiwiki. Loaʻa i ka polokalamu simulation kaʻina nā mea maikaʻi o ka ʻōnaehana simulation naʻauao, nā mea hoʻokomo a me nā koi kaʻina, e unuhi aunoa i ke kaʻina carburizing simulated i loko o ka hale waihona puke, a pili i nā ʻano mea like ʻole me ka hoʻololi iki. Loaʻa iā ia nā pōmaikaʻi o ke kaʻina hana pololei, ka hopena kiʻekiʻe, ka liʻiliʻi liʻiliʻi, ka paʻakikī a me ka paʻakikī o ka carburized layer, ʻaʻohe oxidation kūloko, ʻaʻohe kalapona ʻeleʻele, ʻaʻohe kihi kihi infiltration, a hiki ke ʻike i ka carburization puka makapō. Loaʻa i nā mea hana kaʻina hana nā mea maikaʻi o ke kumukūʻai haʻahaʻa, kiʻekiʻe a me ka hana kiʻekiʻe, ʻike ʻia ka hopena mālama ola.

Nā hiʻohiʻona

1. Kiʻekiʻe naʻauao a me ka pono. Ua lako kūikawā hoʻomohala vacuum haʻahaʻa-puʻe carburizing simulation lako polokalamu.

2. Kiʻekiʻe hoʻoluʻu nui. ua hoʻonui ʻia ka helu hoʻoluʻu e 80% ma o ka hoʻohana ʻana i ka mea hoʻololi wela square kūpono kiʻekiʻe.

3. ʻO ka hoʻolikelike hoʻoluʻu maikaʻi. ʻO ka hoʻoluʻu like ʻana e ka convection mai nā pā pālua.

4. ʻO ke kūlike wela maikaʻi. ua hoʻonohonoho pono ʻia nā mea hoʻomehana 360 degere a puni ke keʻena mehana.

5. ʻAʻohe haumia kalapona ʻeleʻele. Hoʻohana ke keʻena hoʻomehana i ka ʻōnaehana insulation waho e pale ai i ka haumia o ke kalapona ʻeleʻele i ka hana carburizing.

6. Long lawelawe ola , Ke hoʻohana 'ana i ke kalapona manaʻo e like me ka wela-insulation papa oke keʻena hoʻomehana.

7. Good carburized papa mānoanoa uniformity, Carburizing kinoea nozzles ua like hoʻonohonoho 'ia a puni ka wela keʻena, a me ka mānoanoa o ka carburized papa mea like.

8. ʻO ka liʻiliʻi o ka deformation o ka Carburizing workpiece, ʻoi aku ka maikaʻi o ka hana ʻana a me ke kumukūʻai ikehu i mālama ʻia ma mua o 40%.

9. Maikaʻi a maʻalahi hoʻi no ka hoʻonohonoho ʻana i ka polokalamu, kūpaʻa a hilinaʻi hoʻi ka hana mechanical, ʻakomi, semi-akomi a i ʻole e hoʻoweliweli lima a hōʻike i nā hewa.

10. Ka hoʻololi pinepine ʻana i ke kinoea hoʻoheheʻe ʻana i ka peʻa, koho convection ea wela, koho 9 helu ana wela, he mau māka a me ka isothermal quenching.

11. Me ka ʻōnaehana hoʻomalu AI holoʻokoʻa a me kahi ʻōnaehana hana lima keu.